Updated 13 hours ago

Smart Ring Manufacturer: How to Choose a Reliable OEM & ODM Partner

youhong

Introduction: Why Choosing the Right Smart Ring Manufacturer Matters

The global smart ring market is entering a rapid growth phase, driven by rising demand for continuous health monitoring, sleep tracking, sports recovery, and medical-grade wearables. As more brands, healthcare companies, and technology platforms enter this space, one critical decision determines success or failure:

Choosing the right smart ring manufacturer.

Unlike consumer electronics such as earbuds or power banks, smart rings combine biomedical sensors, ultra-low-power electronics, precision manufacturing, algorithms, and regulatory compliance—all within an extremely small form factor. This makes OEM and ODM partner selection far more complex and high-risk.

This guide is written for:

- Brands launching a custom smart ring

- Companies seeking a private label smart ring

- Healthcare or wellness platforms integrating wearable data

- Distributors evaluating a smart ring factory in China

From a manufacturer’s perspective, we explain:

- OEM vs ODM for smart rings

- Core capabilities to evaluate

- R&D, compliance, and production realities

- Cost, MOQ, and customization factors

- A practical partner selection checklist

What Is a Smart Ring Manufacturer?

A smart ring manufacturer designs, develops, and mass-produces wearable rings equipped with sensors, firmware, algorithms, and connectivity for health and activity monitoring.

Unlike assembly-only suppliers, a professional smart ring manufacturer typically provides:

- In-house R&D (hardware + firmware + algorithms)

- Sensor integration (PPG, SpO₂, temperature, ECG, motion)

- Low-power system design

- Mobile app, SDK, or API support

- Regulatory compliance and quality control

- Scalable mass production

This is especially important when working with smart ring OEM or ODM models, where the manufacturer plays a central role in product success.

Smart Ring OEM vs ODM: What’s the Difference?

Understanding OEM and ODM is essential before contacting any smart ring factory.

Smart Ring OEM (Original Equipment Manufacturer)

In an OEM model:

- You provide product requirements, branding, and positioning

- The manufacturer handles engineering, manufacturing, and assembly

- Customization focuses on:

- Hardware configuration

- Firmware features

- App branding

- Packaging and accessories

OEM is ideal for brands that:

- Have product strategy but not hardware R&D

- Want faster time-to-market

- Need moderate customization at controlled cost

Smart Ring ODM (Original Design Manufacturer)

In an ODM model:

- The manufacturer provides pre-developed reference designs

- You select, modify, and brand an existing platform

- Customization includes:

- Appearance

- Sensor combinations

- Software features

- Algorithm tuning

ODM is ideal for brands that:

- Want to launch quickly

- Prefer lower development risk

- Need proven hardware and algorithms

A reliable smart ring manufacturer should support both OEM and ODM, allowing flexibility as your product roadmap evolves.

Why China Is the Global Hub for Smart Ring Manufacturing

When searching for a smart ring factory in China, many brands focus only on cost. In reality, China leads smart ring manufacturing due to:

1. Integrated Supply Chain

- Biomedical sensors

- Low-power MCUs & BLE chipsets

- Precision CNC & injection molding

- Battery and charging solutions

2. Wearable-Specific Manufacturing Experience

Smart rings require:

- Micron-level precision

- Ultra-small PCB design

- Stable skin-contact materials

- Long-term reliability testing

3. Scalability

From pilot runs (1,000–3,000 units) to mass production (100k+), Chinese manufacturers can scale rapidly.

However, not all factories are equal—and this is where careful selection matters.

Core Capabilities of a Reliable Smart Ring Manufacturer

1. In-House R&D and Engineering

A serious smart ring manufacturer must have internal teams for:

- Hardware design (PCB, antenna, power management)

- Firmware and BLE optimization

- Sensor fusion algorithms

- Mechanical and industrial design

Red flag: factories that outsource all R&D.

2. Health Sensor & Algorithm Expertise

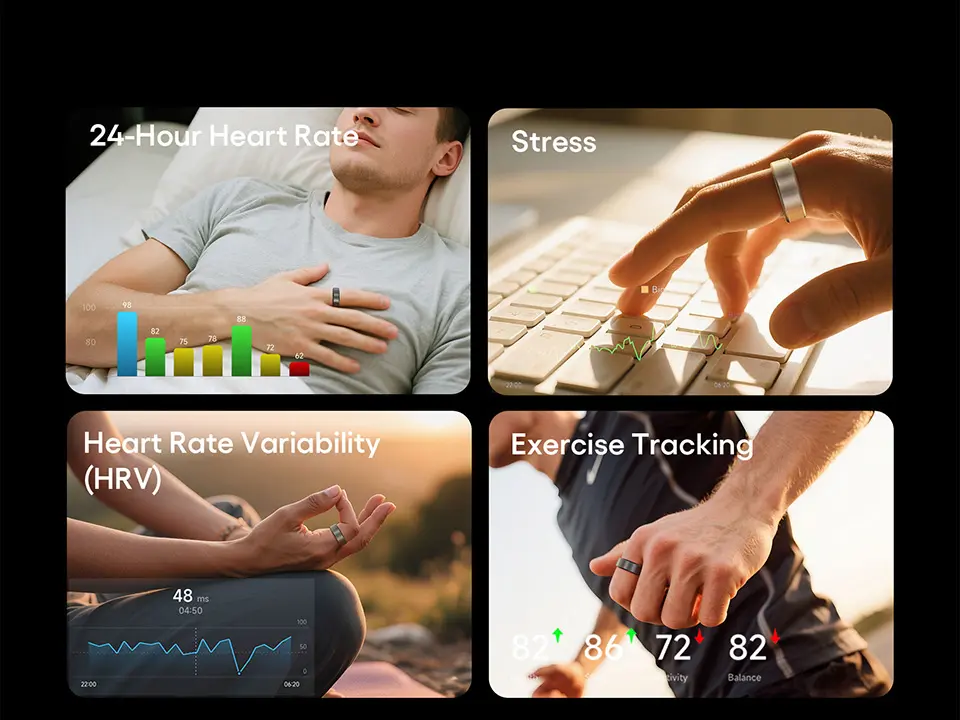

Smart rings typically include:

- PPG sensors (heart rate, HRV)

- SpO₂ (blood oxygen)

- Skin temperature

- Motion sensors (accelerometer, gyroscope)

- Optional ECG modules

But data accuracy depends on algorithms, not sensors alone. Ask about:

- Signal processing methods

- Motion artifact suppression

- Calibration and validation processes

3. Ultra-Low-Power Design

Battery life is one of the biggest challenges in smart rings.

A capable smart ring OEM should demonstrate:

- BLE power optimization

- Sleep-mode architecture

- Sampling rate control

- Efficient firmware scheduling

Without this expertise, battery life claims are unrealistic.

4. Customization & Private Label Capability

For custom smart ring or private label smart ring projects, evaluate:

- Ring size range (men/women/unisex)

- Material options (titanium, stainless steel, ceramic)

- Surface finishes and colors

- Logo engraving and packaging

- App UI/UX branding

- Firmware feature toggles

A true ODM/OEM partner supports customization without breaking stability.

5. Software Ecosystem: App, SDK, and API

Modern smart rings are not standalone hardware.

Your manufacturer should support:

- iOS & Android apps

- Cloud infrastructure (optional)

- SDK for third-party integration

- API for data access and platforms

This is critical for:

- Healthcare platforms

- Insurance programs

- Corporate wellness solutions

- Web3 or data-driven services

Compliance, Certifications, and Quality Control

Key Certifications to Expect

A reliable smart ring manufacturer should support:

- CE (EU market)

- FCC (US market)

- RoHS / REACH

- ISO 9001 / ISO 13485 (for medical wearables)

For medical or wellness applications:

- Data privacy compliance (GDPR, HIPAA readiness)

- Clinical validation support (where applicable)

Manufacturing Quality Control

Ask about:

- Incoming material inspection

- In-process testing

- Aging and reliability tests

- Waterproof and sweat resistance testing

- Final functional calibration

Quality is not optional in wearable health devices.

Cost Structure, MOQ, and Lead Time Explained

Typical Cost Components

- Hardware BOM

- Sensors and chipsets

- Firmware & algorithm licensing

- App and cloud services

- Tooling and molds

- Certification costs

MOQ Expectations

- ODM models: lower MOQ

- OEM/custom projects: higher MOQ due to tooling

Lead Time

- ODM: 3–6 months

- OEM: 6–12 months (depending on complexity)

A transparent manufacturer explains costs clearly—no surprises.

Common Mistakes When Choosing a Smart Ring OEM/ODM

- Choosing based on price only

- Ignoring algorithm and software depth

- Underestimating certification timelines

- Working with factories lacking wearable experience

- No long-term roadmap support

Smart Ring Manufacturer Selection Checklist

Before signing, confirm:

- ✔ In-house R&D team

- ✔ Proven smart ring projects

- ✔ Sensor & algorithm expertise

- ✔ Low-power design capability

- ✔ Customization flexibility

- ✔ App / SDK / API support

- ✔ Compliance experience

- ✔ Scalable production capacity

Why J-STYLE Is a Trusted Smart Ring Manufacturer

J-STYLE (Jointcorp / Youhong Medical) is a vertically integrated smart ring manufacturer specializing in:

- Smart ring OEM & ODM solutions

- Medical and wellness-grade wearables

- Ultra-low-power wearable design

- Health algorithms and data platforms

- Global compliance and mass production

With experience serving:

- Health brands

- Technology companies

- Medical partners

- Corporate wellness programs

J-STYLE supports the entire lifecycle—from concept and R&D to certification and global delivery.

Conclusion: Build with the Right Smart Ring Partner

Launching a smart ring is not just about hardware—it’s about data accuracy, reliability, scalability, and trust.

Choosing the right smart ring manufacturer, OEM, or ODM partner ensures:

- Faster time-to-market

- Lower development risk

- Better product performance

- Long-term brand success

If you are planning a custom smart ring or private label smart ring, working with an experienced manufacturer makes all the difference.

About the Author

Kyler is a senior content marketing specialist at J-Style(Jointcorp|Joint Chinese Ltd | Youhong Medical), a leading smart ring, smart band, and smart watch manufacturer and supplier in China. With 8 years of experience in the wearable tech industry, he creates professional content for global B2B buyers seeking reliable factory, wholesale, OEM/ODM, and SDK/API solutions. At J-Style, Kyler focuses on helping partners understand the value of high-quality Chinese smart wearables and how J-Style’s innovative manufacturing capabilities support scalable business growth.